Description

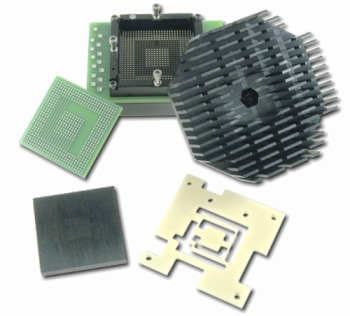

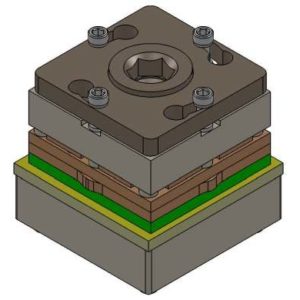

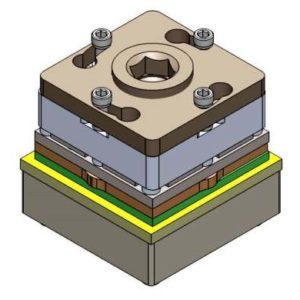

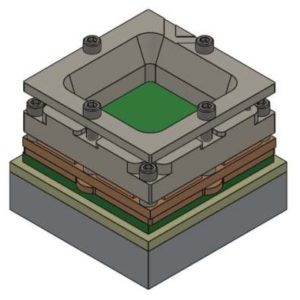

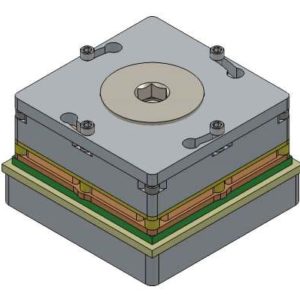

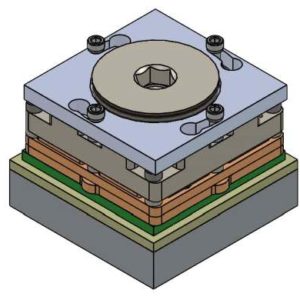

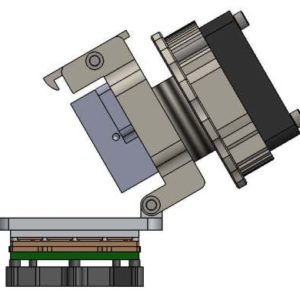

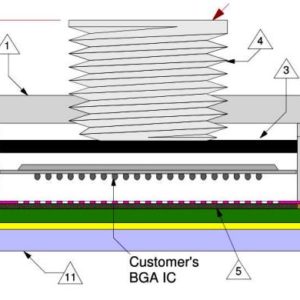

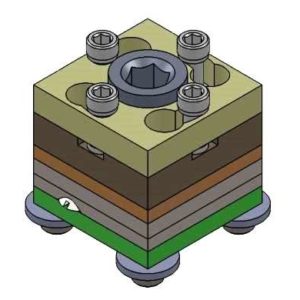

Ironwood Electronics SM/SMP socket uses SM & SMP contact technology for high speed, low inductance, high endurance and wide temperature applications. SM Contact is a unique contact that has precise silver balls held together by a proprietary conductive formulation. These conductive columns (diameter optimized for 50 ohm impedance) are suspended in a non-conductive flexible elastomer substrate with a patented solid core for enhanced durability and reliable performance over time, temperature and cycles. This flexible substrate is very compliant and resilient and enables the conductive columns to revert back to original shape when the force is removed. Solutions are available for 0.25mm to 1.27mm LGA, BGA, QFN, CSP, POP, WLP and other packages.

| PART NUMBER |

RoHS | IC Size X (mm) |

IC Size Y (mm) |

IC Size Tolerance (mm) |

Top Pitch (mm) |

IC Array X |

IC Array Y |

Max Pincount |

| SM-BGA-9000 | Yes | 23 | 23 | 0.2 | 0.8 | 27 | 27 | 729 |

| SM-BGA-9006 | Yes | 16 | 16 | 0.15 | 0.8 | 19 | 19 | 361 |

| SM-BGA-9007 | Yes | 9.75 | 6 | 0.1 | 0.75 | 13 | 8 | 102 |

| SM-BGA-9009 | Yes | 40 | 40 | 0.1 | 1 | 39 | 39 | 680 |

| SM-BGA-9010 | Yes | 21 | 21 | 0.2 | 0.8 | 25 | 25 | 564 |

| SM-BGA-9011 | Yes | 23 | 23 | 0.2 | 1.27 | 18 | 18 | 224 |

| SM-BGA-9012 | Yes | 9.76 | 6 | 0.1 | 0.75 | 13 | 8 | 74 |

| SM-BGA-9013 | Yes | 27 | 27 | 0.2 | 1.27 | 20 | 20 | 400 |

| SM-BGA-9014 | Yes | 29 | 29 | 0.2 | 1.27 | 22 | 22 | 484 |

| SM-BGA-9015 | Yes | 13.76 | 13 | 0.1 | 0.75 | 16 | 15 | 240 |

| SM-BGA-9016 | Yes | 8.5 | 10.5 | 0.1 | 0.5 | 16 | 20 | 320 |

| SM-BGA-9018 | Yes | 15 | 15 | 0.2 | 0.8 | 18 | 18 | 288 |

| SM-BGA-9019 | Yes | 19 | 19 | 0.2 | 1 | 18 | 18 | 324 |

| SM-BGA-9020 | Yes | 5 | 5 | 0.2 | 0.5 | 9 | 9 | 81 |

| SM-BGA-9021 | Yes | 12 | 12 | 0.1 | 0.8 | 14 | 14 | 196 |

| SM-BGA-9022 | Yes | 27 | 27 | 0.1 | 1 | 26 | 26 | 388 |

| SM-BGA-9023 | Yes | 5 | 5 | 0.1 | 0.5 | 9 | 9 | 50 |

| SM-BGA-9024 | Yes | 31 | 31 | 0.2 | 0.8 | 38 | 38 | 1290 |

| SM-BGA-9025 | Yes | 16 | 16 | 0.2 | 0.5 | 30 | 30 | 788 |

| SM-BGA-9027 | Yes | 7 | 7 | 0.1 | 0.5 | 12 | 12 | 144 |

| IC Ball H. Min (mm) |

IC Ball H. Max (mm) |

IC Total H. Max (mm) |

IC Ball Coplanarity (mm) |

IC Ball D. Max (mm) |

IC Top Surface |

Socket Lid |

Heat Sink |

| 0.3 | 0.5 | 2.5 | 0.15 | 0.5 | Mold Cap | Swivel | Yes |

| 0.25 | 0.35 | 1.7 | 0.12 | 0.38 | Flat | Swivel | no |

| 0.28 | 0.43 | 3.29 | 0.1 | 0.53 | Flat | Swivel | no |

| 0.4 | 0.6 | 1.62 | 0.2 | 0.7 | Flat | Clam shell | no |

| 0.35 | 0.45 | 2.5 | 0.2 | 0.55 | Flat | Clam shell | yes |

| 0.762 | 2.21 | 0.2 | 0.762 | Flat | Swivel | yes | |

| 0.28 | 0.43 | 3.29 | 0.1 | 0.53 | Flat | Clam shell | no |

| 0.66 | 2.375 | 0.2 | 0.762 | Flat | Swivel | no | |

| 0.66 | 2.738 | 0.2 | 0.762 | Flat | Swivel | no | |

| 0.28 | 0.43 | 3.63 | 0.1 | 0.4 | Flat | Clam shell | no |

| 0.17 | 0.27 | 0.92 | 0.08 | 0.35 | Flat | Swivel | no |

| 0.22 | 0.2 | 1.3 | 0.1 | 0.42 | Mold Cap | Swivel | no |

| 0.4 | 0.6 | 2.92 | 0.15 | 0.7 | Mold Cap | Clam shell | yes |

| 0.11 | 0.25 | 1 | 0.08 | 0.35 | Flat | Swivel | no |

| 0.4 | 1 | 0.08 | 0.5 | Flat | Swivel | no | |

| 0.4 | 0.6 | 3 | 0.15 | 0.7 | Flat | Clam shell | no |

| 0.15 | 0.25 | 0.77 | 0.08 | 0.35 | Flat | Swivel | no |

| 0.5 | 0.6 | 3.4 | 0.2 | 0.55 | Mold Cap | Clam shell | yes |

| 0.15 | 0.26 | 1.7 | 0.08 | 35 | Flat | Swivel | no |

| 0.16 | 0.26 | 1.2 | 0.08 | 0.37 | Flat | Clam shell | no |