|

Prototype and Production Test Applications demand high bandwidth followed by high compliance, low resistance and high temperature.

• Elastomers have high bandwidth

• Elastomers have low resistance

• Elastomers have low compliance

• Due to small thickness and mechanical coupling

• Elastomers have limited temperature range

• Due to the inherent process of silicone rubber

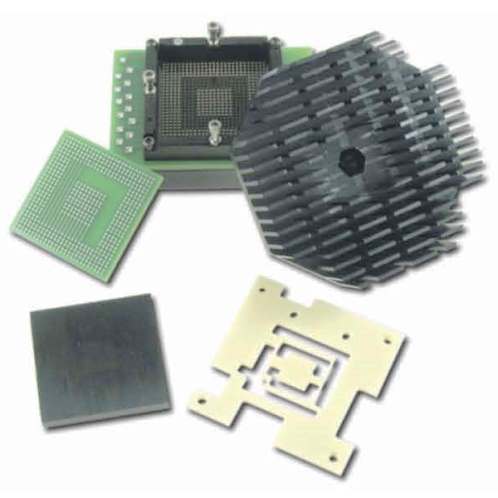

SM is a new elastomer technology that has silver balls held in a conductive column like buttons which are embedded in a non-conductive silicone rubber on a proper pitch that provides high compliance and extreme temperature ranges. The non-conductive rubber has a core in the middle to enable compression stop feature. SM is available for BGA, LGA, QFN, PoP and other packages from 0.25mm to 1.27mm.

The silver ball matrix contact technology is also available with a protective plunger matrix (a gold plated copper cylinder) that sits on top of the conductive columns. This plunger matrix protects the conductive column from contamination from various solder ball interfaces. A quickly replaceable plunger matrix enables minimal downtime during final production test. The product family code for

this line of sockets is SMP. SMP is for ATE production test and is available for BGA, LGA, QFN, PoP and other packages from 0.25mm to 1.27mm.

|